Free Shipping over $49

In the realm of photometry, or light measurement, professionals utilize two distinct tools: the goniophotometer and the integrating sphere. Each serves a similar purpose—measuring light output—but excels in different scenarios based on unique design principles.

| Goniophotometer | Integrating Sphere |

|  |

Fundamental Distinctions Between The Two Devices

1. Accuracy factors

2. Application scope

3. The testing discrepancy between spotlight (with a narrow beam) and flood light (with a wide beam)

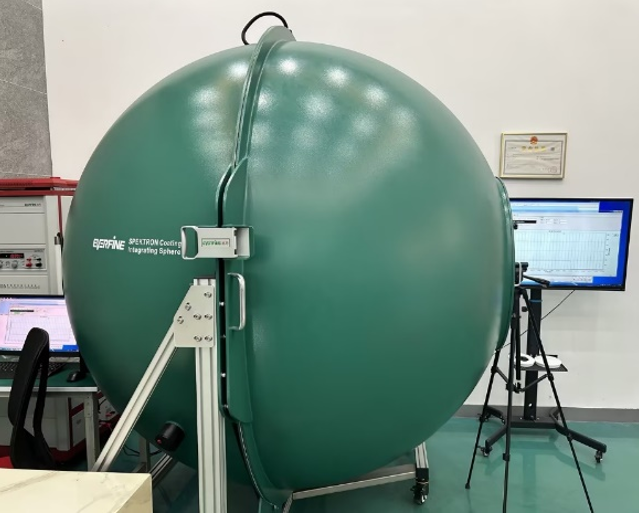

The Basic Features of Integrating Spheres

1. Key structures of the integrating sphere

- Coating: The inner wall has a special reflective coating to produce diffuse reflection and compare it with the data of the calibration lamp to obtain accurate test data.

- Baffles: It is used to prevent direct light from the light source enters the detector.

2. Size of the integrating sphere

- In theory, the larger the integrating sphere, the better, as this minimizes the impact of apertures and internal protrusions on the uniform distribution of light sources.

- When testing a spotlight flashlight that features a narrow beam, the size of integrating sphere has a great impact on the test results. A smaller integrating sphere will cause the light baffle to be closer to the light inlet, and the light spot may leak from the edge of the light baffle, resulting in a higher test value. When there is no light leakage, the data will be low.

- In contrast, a larger integrating sphere has a larger light baffle, which can reduce the impact of light source leakage. Therefore, when different-sized integrating spheres test the same light source, the data of the smaller integrating sphere is usually higher.

Reasons for The Luminous Flux of The Spotlight Being Lower Than Its Actual Value

Now, you probably would like to know more about

- Why goniophotometers excel in measuring directed light sources like LEDs and car headlights.

- Or you might wonder why goniophotometers offer higher precision when measuring the luminous flux of the spot beam.

To answer this question, we invite you to come closer to our lab.

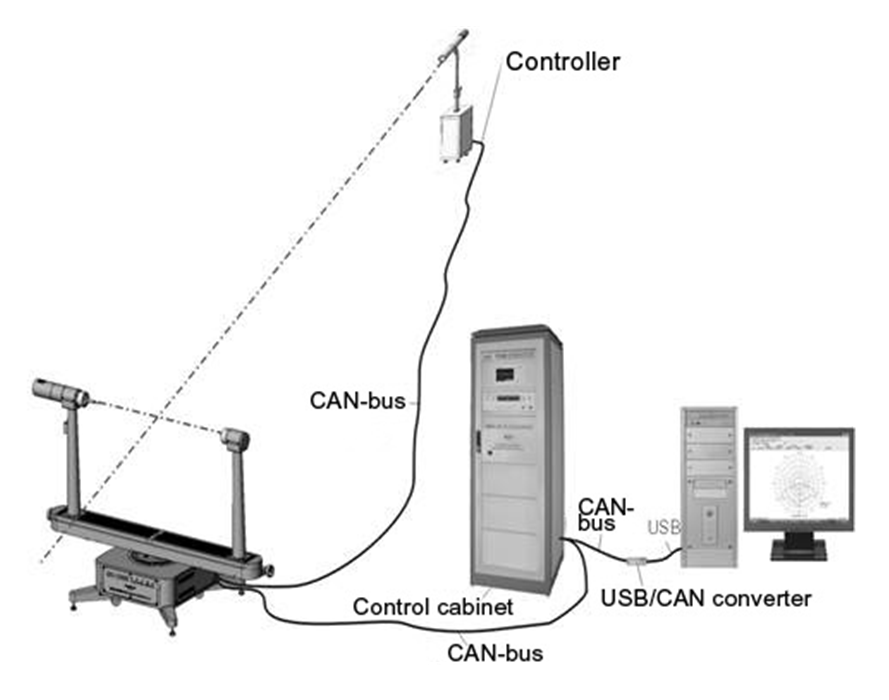

Except for integrating sphere, ACEBEAM Laboratory also has the advanced version Go-2000 Goniophotometer, which is known as a horizontal-type goniophotometer.

The system encompasses an automatic dual-axis turntable (the Go-2000), a goniophotometer turntable controller, a computer, control software, a dedicated photometer, and a power meter, among other components.

Diagram 1: Schematic Diagram of the Testing System

The GO-2000 goniophotometer assesses the illumination distribution performance of luminaires by rotating the test sample while keeping the detector stationary.

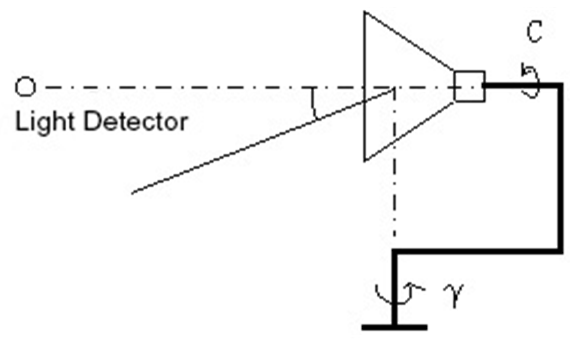

The fundamental principle of this testing method, illustrated by the C-γ coordinate system, is depicted in Diagram 2 below.

Diagram 2: Schematic Diagram of Luminaire Measurement Principle Using the C-γ System

Spotlight with Narrow beam VS Flood light with wide beam

Both narrow and wide beams can impact the measurement of luminous flux using an integrating sphere, though the effects differ:

A light source emitting a narrow beam can lead to non-uniform illumination within the integrating sphere if the beam is not adequately diffused. This may result in inaccuracies in the measured luminous flux due to hotspot formation or underutilization of the sphere's surface for light collection.

To mitigate this, additional diffusers or baffles might be necessary to ensure proper light mixing.

A wide beam source tends to distribute light more evenly across the sphere, promoting better light diffusion and a more uniform illuminance on the sphere's walls.

This generally results in more accurate luminous flux measurements since it aligns well with the integrating sphere's design principle of creating a uniform radiation field.

Conclusion

Goniophotometer offers higher precision when measuring the luminous flux of spotlights, with minimal uncertainty factors, although it requires longer test durations and stringent environmental conditions.

In contrast, integrating sphere is better suited for measuring the luminous flux of floodlights, leveraging the principle of light reflection to yield precise lumens measurements. Nonetheless, its limitations may lead to less accurate data when applied to spotlights due to inherent constraints.

In practical applications, we meticulously select the appropriate testing equipment and methodologies tailored to each product to ensure the precision of our measurements.